The aerospace industry relies on multiple plating processes for a diverse range of products internally and externally. Aerospace electroplating and production of these components, used by both the commercial and defense industry, requires an elevated level of precision and consistency. These standards are set by the International Aerospace Quality Group and recognized with AS9100 certification.

NADCAP Certification

NADCAP certification is a specialized accreditation based on specific processes related to the aerospace industry. Specialized auditors with experience in the aerospace industry conduct the actual process audits using specific criteria defined by NADCAP. This in-depth critical process audits to guarantee that Silvex NADCAP finishes meeting the tightly defined industry standards necessary when producing aerospace components.

AS9100 Certification

AS9100 certification shows full adherence to the quality management systems standards as stated by the International Aerospace Quality Group. These are unique standards specific to the aerospace industry’s challenges; this certification is crucial for any company servicing the aerospace industry.

Aerospace Electroplating Finishes

Anodizing

Anodizing non-ferrous metal parts result in a controlled layer of oxide coating. Usually performed in a sulfuric acid solution, this coating provides increased corrosion resistance and insulation. Type 2 is the most common anodizing process and can range from 5 to 15 microns, while type 3, also known as hard anodizing, allows for a coating thickness up to 75 microns. Silvex can certify thicknesses of anodized parts to +/- 5 microns. The deep pores created by anodizing make it an ideal application for anything requiring adhesion. This greater surface area allows the metal to be dyed in many colors and greater for retention of adhesives, primers, and lubricants. Turbine engines such as fan shrouds and compressors require anodized components most prominently for durability.

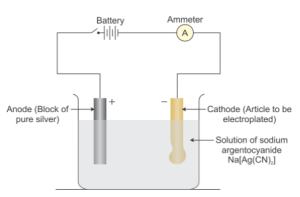

Silver Plating

Silver plating can be deposited onto aluminum, brass, bronze, copper, steel, and stainless-steel alloys. The finish can be matte, semi-bright, or bright. Silver can be plated as thin as 1 micron, with most applications requiring thicknesses ranging from 10 to 40 microns depending on the application. Thinner plating is desired for its solderability, while thicker silver application provides high levels of wear resistance. In aerospace, this is most prevalent in turbine engines and electrical components such as industrial electrical connectors. Silver’s notable advantages as an aerospace electroplating company are high conductivity, solderability, and heat resistance. Turbine engines subject their components to extreme levels of heat and usage, making silver plating vital for heat and friction resistance.

Silver plating can be deposited onto aluminum, brass, bronze, copper, steel, and stainless-steel alloys. The finish can be matte, semi-bright, or bright. Silver can be plated as thin as 1 micron, with most applications requiring thicknesses ranging from 10 to 40 microns depending on the application. Thinner plating is desired for its solderability, while thicker silver application provides high levels of wear resistance. In aerospace, this is most prevalent in turbine engines and electrical components such as industrial electrical connectors. Silver’s notable advantages as an aerospace electroplating company are high conductivity, solderability, and heat resistance. Turbine engines subject their components to extreme levels of heat and usage, making silver plating vital for heat and friction resistance.

Platinum Plating

The demand for platinum equates to nearly 8 million ounces annually, with more than half being used to coat catalytic converters for emission handling. Platinum plating creates parts with high levels of durability, as well as corrosion and heat resistance. Silvex can plate platinum on parts up to 12” in length. This can be done on brass, castings, copper, invar, Kovar, steel, stainless steel, and titanium. Depending on the application, the finish commonly ranges from .05 to 5 microns. The finish color will range from tin white to matte gray, depending on the material, process, and plating thickness. The aerospace industry uses platinum plating in many high heat and wear situations due in part to its high melting point of over 1750*C and its resistance to tarnish and acidity. Turbine blades are routinely exposed to temperatures above 1000*C while rotating near 20,000 rpm. These blades are coated in platinum to increase the service life of the engines.

Please contact us at Silvex, Inc. today to learn more about our capabilities for aerospace electroplating requirements.