The hard anodizing process, or hard coat anodizing, is a specialized surface coating treatment that greatly enhances the material properties of aluminum, especially for aluminum-made products, parts, and components used in government and defense-related applications. Hard anodizing is achieved through an electrochemical reaction that increases the thickness of the naturally occurring oxide layer on aluminum surfaces. The process can create a relatively thick layer of hard aluminum oxide on the surface, allowing a coating thickness of up to 75 microns. The hard anodizing process, called Type III anodizing, is the standard for government and defense contracts that meets U.S. military specification Mil-A-8625 standards.

A prime characteristic of hard anodizing aluminum surfaces is the improved retention of colored dye coatings. Coyote Brown hard anodizing is the specialized color-coated finishing for hard anodized components. The color was developed by Silvex, Inc. and Sig Sauer for US Army NGSW (Next Generation Squad Weapon) small arms systems program applications. Silvex Inc. is proud to partner with Sig Sauer in developing Coyote Brown anodizing for their submission for the U.S. Army’s NGSW program https://www.silvexinc.com/industries/defense/.

The importance of Coyote Brown hard anodizing military hardware cannot be understated. Coyote Brown matches equipment to natural colors in certain environments where concealment and operational effectiveness are crucial to the mission. In other words, Coyote Brown provides a neutral and effective camouflage color for many operational terrains, where stealth and blending in are key considerations.

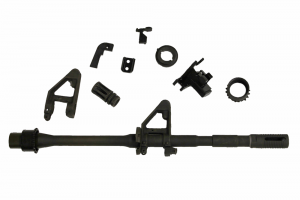

The material’s enhanced properties and distinctive camouflaged finish make it ideal for various military equipment and components. Common applications for Coyote Brown, hard anodizing in defense contracts, include many firearm components, such as receivers, handguards, frames, and scopes. The process is often used on tactical gear like helmets and body armor plates. Weapon accessories like rifle scopes, mounts, and bipods can also feature Coyote Brown anodizing to match the firearm’s finish and provide protection. Add ammunition containers to the list as well. Containers hard anodized with a coating of Coyote Brown make them more robust and corrosion-resistant for long-term storage in a wide range of environments.

The Importance of Coyote Brown Hard Anodizing

Regarded for its low density and lightweight, aluminum and aluminum alloys have long been a material choice in manufacturing for aerospace and defense-related applications. Though light in weight compared to other metals, aluminum is not only a solid material but easily malleable. It’s highly conductive yet non-magnetic. It’s non-toxic, does not spark, and is non-combustible. In the context of military applications, the material is ideal. When subjected to Coyote Brown hard anodized surface treatment, it further improves the material properties of military hardware and equipment, proving beneficial in several significant and meaningful ways, including:

Corrosion Resistance

Coyote Brown Hard Anodizing creates a corrosion-resistant surface on metal parts. Military hardware and aerospace equipment are often subjected to harsh and corrosive environments, from marine to desert conditions. Components hard anodized are far less prone to corrosion, which ensures their longevity but especially their reliability of the applications in critical situations.

Increased Resilience and Durability

Coyote Brown hard anodizing increases the durability and resilience required of military hardware. As a material, aluminum is well regarded for its long-lasting durability over time and its capacity to withstand the toughest and most severe conditions. Hard anodizing produces a surface layer that is three times stronger than the aluminum material’s natural base. It does not peel, chip, or flake. The hard anodized layer, combined with Coyote Brown coating, provides the durability essential for military equipment with frequent use and heavy loads. Such equipment hard anodized with Coyote Brown can withstand extended service life without the need for frequent maintenance or replacement.

Wear and Abrasion Resistance

Hard anodizing offers ten times more wear resistance in testing than ordinary anodized aluminum. This is due to the electrochemical process of hard anodizing. Once the thicker oxide layer has been created, it becomes part of the aluminum’s base, providing a hard, wear-resistant surface with enhanced resistance to abrasion. The process allows Coyote Brown hard anodized parts and components to better retain their color, with increased resistance to wear and abrasion.

Improved Performance

In aerospace and defense applications, the performance of components can be critical for mission success and safety. Coyote Brown hard anodizing can improve the performance of parts by reducing friction, enhancing wear resistance, and maintaining dimensional stability under extreme conditions. This, in turn, contributes to the overall effectiveness and reliability of the equipment.

As a process, Coyote Brown hard anodizing enhances the performance and longevity of defense equipment, increases its wear and corrosion resistance, and provides camouflaged finishing to hardware and equipment. The process helps ensure that military equipment remains functional and effective under the harshest conditions while minimizing its detection in the field.

Contact the Hard Anodize Experts at Silvex Inc.

Silvex Inc. offers Coyote Brown hard anodizing and other advanced plating technologies for defense industry applications, including partnering with Sig Sauer in developing Coyote Brown anodizing for their submission for the U.S. Army’s NGSW program. We are NADCAP certified and maintain an ITAR (International Traffic in Arms) certification and a Federal Firearms License. Contact us today for more information on our advanced plating technologies for defense industry applications.