Silvex, Inc. has been providing flatware electroplating services for many of the world’s largest hotel and restaurant supply companies for over three decades. Consistent results and acute attention to detail make Silvex the definitive flatware plating company in the northeast, with a large presence in the global market. Offering 6, 7, 10, 20, and 33-micron plating thickness, Silvex’s custom-designed and built flatware plating line is ideal for producing consistent, reliable coating thickness while allowing flexibility to adjust the process based on customer-specific needs.

The Silvex Standard

Silvex, Inc. sets itself apart from other flatware platers in every step of the process. Before plating, all flatware is subject to a proprietary multistage cleaning process. Utilizing ultrasonic cleaners, all residual compounds are removed from the raw parts, creating an ideal surface for the plating adhesion. A 3-micron nickel plate layer is then applied before plating. This layer is vital for increasing the corrosion resistance of the flatware and producing a harder, brighter finish on the completed parts. Parts are then electroplated with a 99.9% pure silver finish to the desired thickness defined by the customer.

Silvex, Inc. sets itself apart from other flatware platers in every step of the process. Before plating, all flatware is subject to a proprietary multistage cleaning process. Utilizing ultrasonic cleaners, all residual compounds are removed from the raw parts, creating an ideal surface for the plating adhesion. A 3-micron nickel plate layer is then applied before plating. This layer is vital for increasing the corrosion resistance of the flatware and producing a harder, brighter finish on the completed parts. Parts are then electroplated with a 99.9% pure silver finish to the desired thickness defined by the customer.

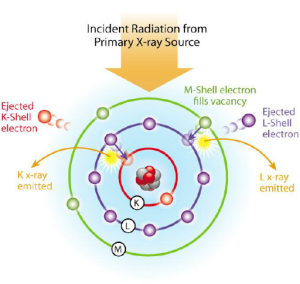

All stainless steel flatware orders are certified by the quality assurance team using XRF. X-ray fluorescent spectroscopy is performed by imparting an initial x-ray source on the part and measuring the fluorescent x-rays emitted. Each element produces a unique set of characteristics when emitting fluorescent x-rays. The data from the emitted sample are then sent through a CPU to analyze the spectral data, resulting in complete data describing the composition of the material being x-rayed. The quality assurance department then translates this data to determine that the appropriate thickness for the plating has been achieved.

Contact our experienced team at Silvex, Inc. to learn more about our flatware electroplating services or to inquire about a specific project.